Turning industrial reality into digital clarity

Gain instant access to accurate 3D data for planning, safety, and maintenance — all without shutting down operations.

eSite – bringing industrial environments to life virtually

At eSite, we specialize in advanced 3D reality capture and as-built modeling for industrial plants, factories, and construction sites.

Our mission is simple: turn your physical site into a precise, interactive digital model — enabling you to make better decisions, reduce costly rework, and keep projects on track.

With cutting-edge scanning technology, proven workflows, and years of industry expertise, we deliver accurate, secure, and actionable data that supports every stage of your project lifecycle.

100+

Sites scanned

15+

Industries served

57

Net Promoter Score

Capture & Digitize Your Facility

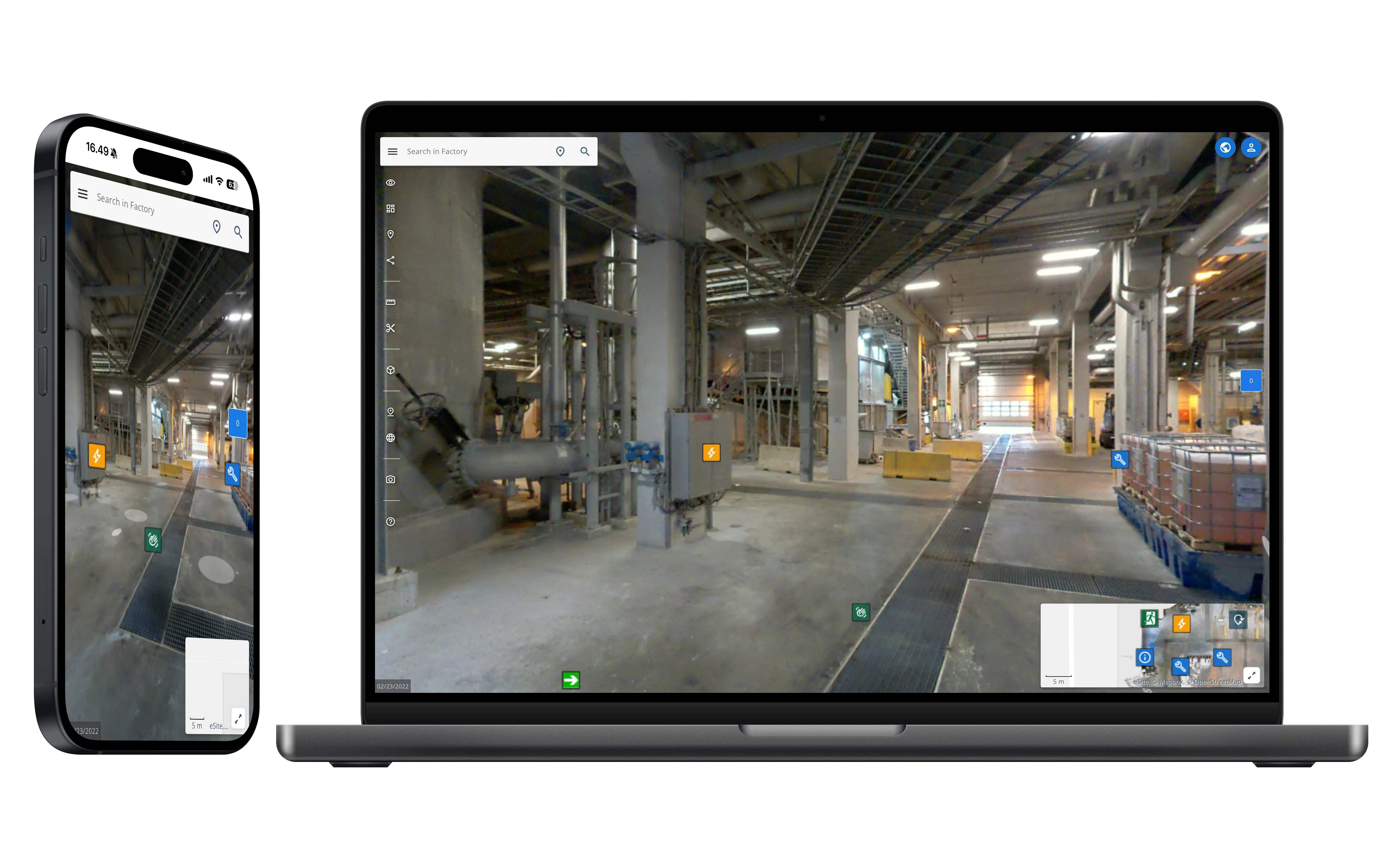

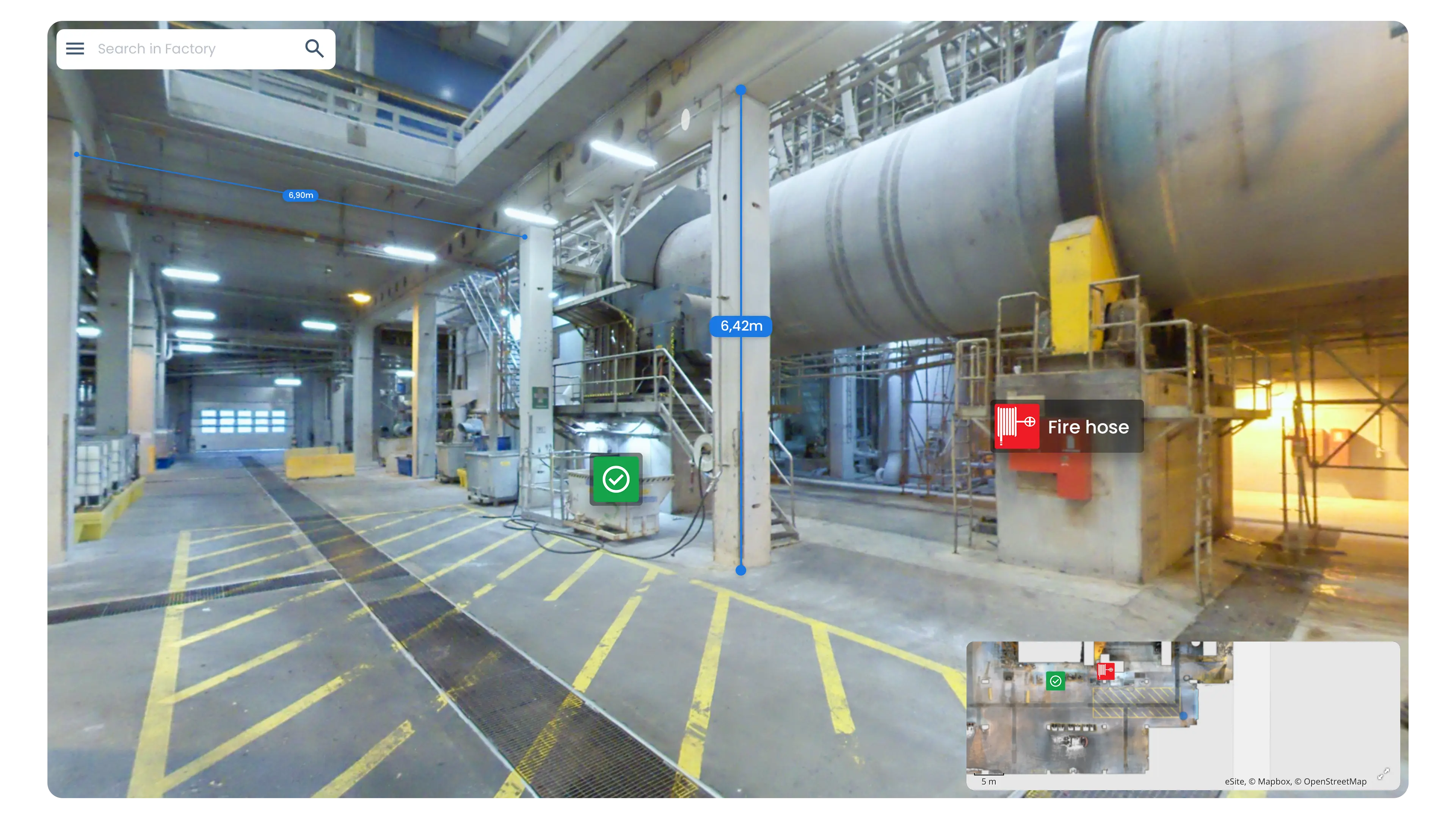

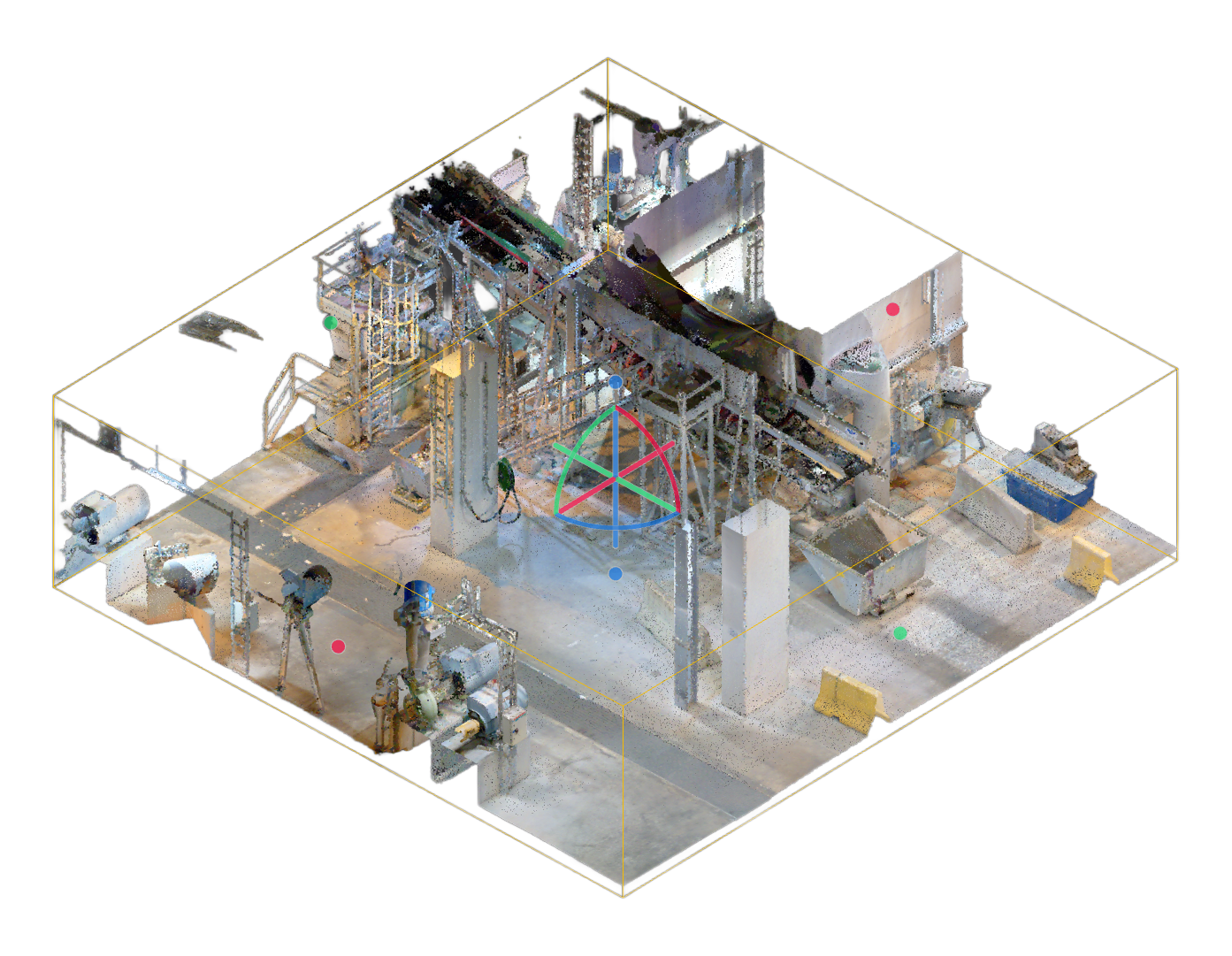

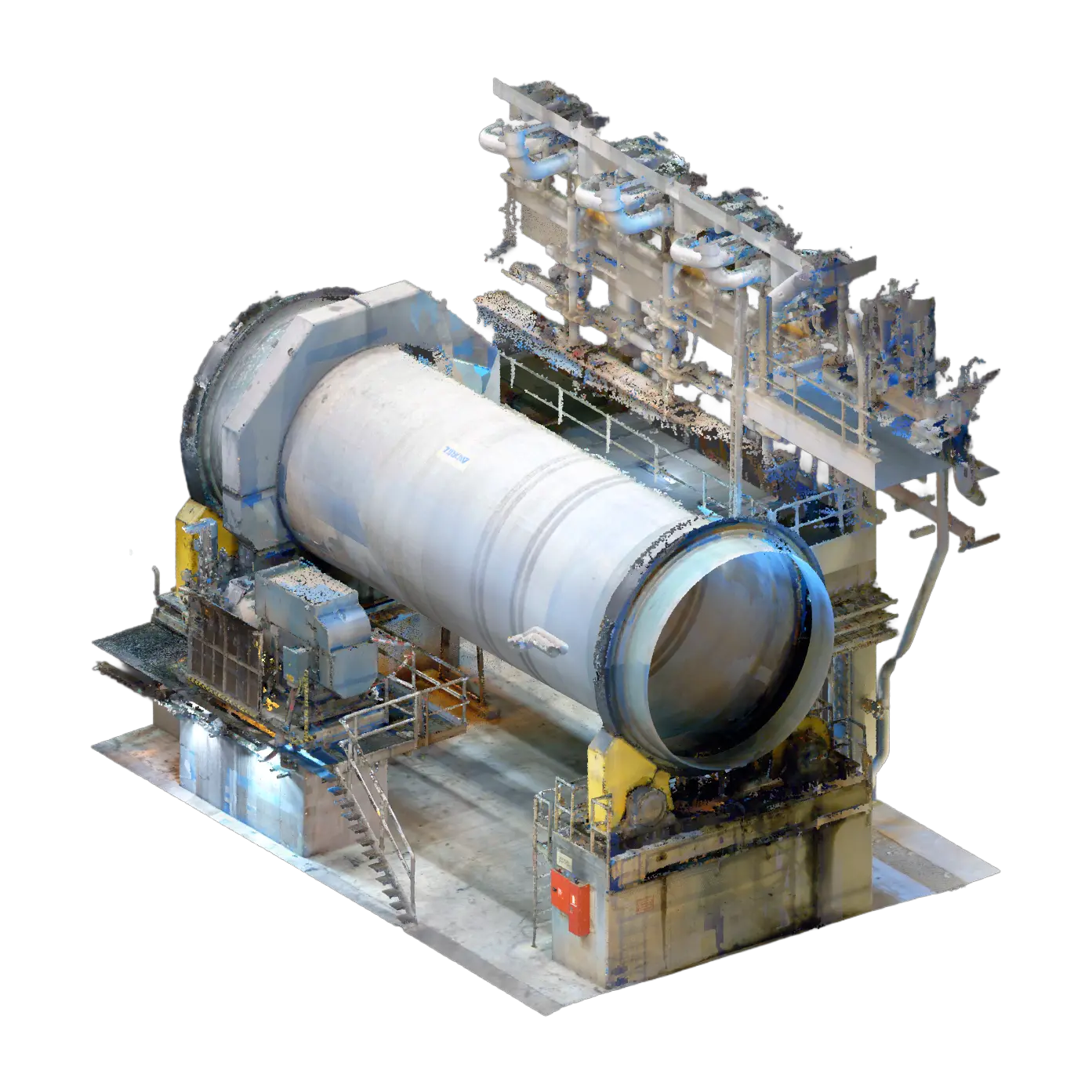

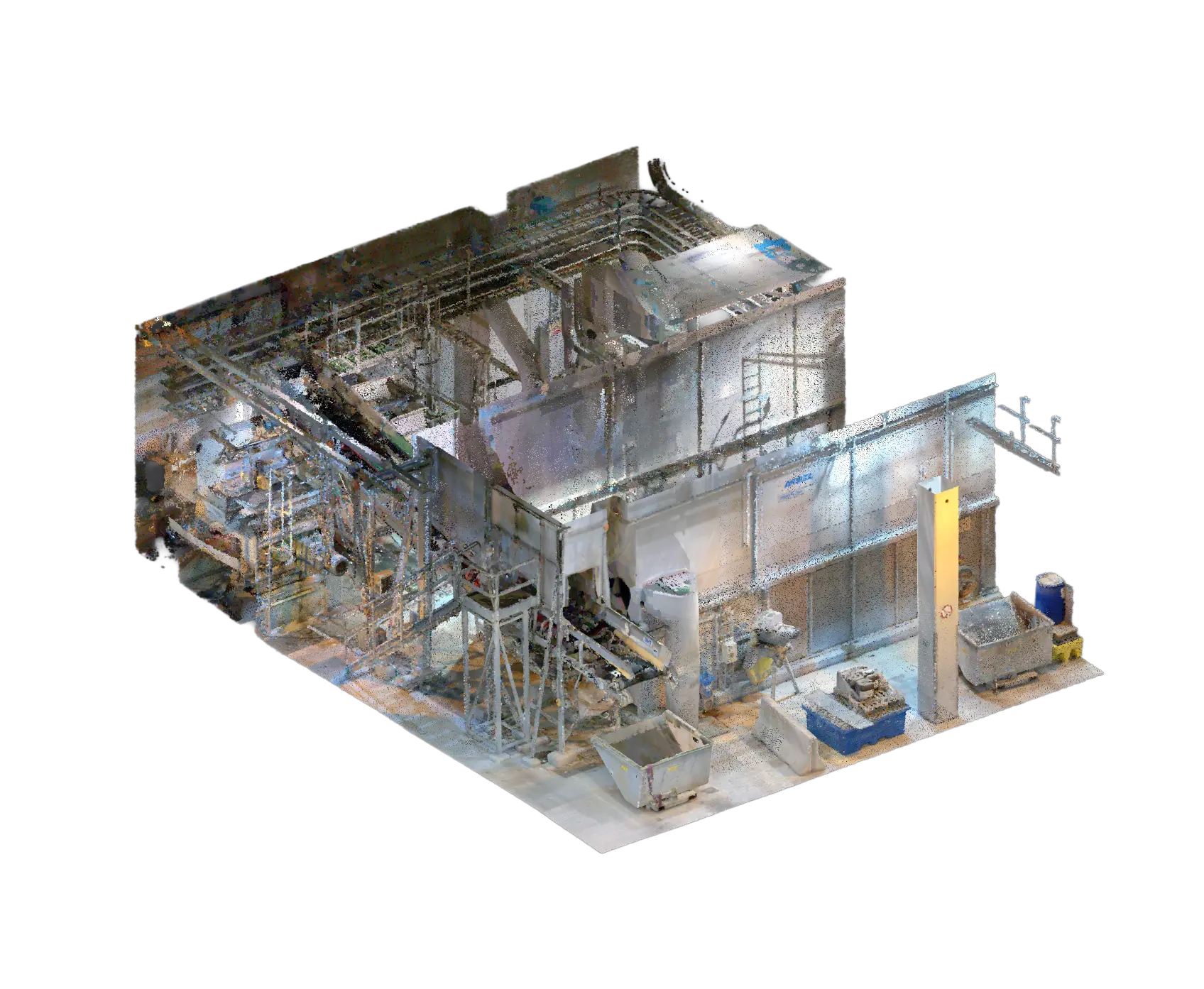

In a few days, we can capture and digitize your entire plant with exceptional accuracy and detail. By combining the most effective methods and latest technology, we create a high-fidelity digital representation of your site – enabling you to virtually navigate the facility anywhere, take measurements, capture images, and extract precise 3D data for planning, analysis, and decision-making.

Fast and accurate digital capturing

Virtual navigation

Support for planning and decision-making

Tools for improving your daily work

While our core focus is on reality capture and 3D modeling, we also support clients in identifying the most effective ways to integrate VR technologies where they add real value. With years of experience across industrial sectors, we make it easy to incorporate VR into your processes – whether for visualization, remote collaboration, or enhanced training – ensuring it’s both practical and impactful.

VR Solutions

Practical and effective

Tailored system integrations

From single users to full enterprise rollouts, we support direct integration – including Single Sign-On (SSO). All data is securely stored on certified, protected servers in Europe, ensuring its safety and compliance with industry standards.

We offer trainings and workshops that help you to maximize the value of eSite services.

Scalability to your needs

Identity integrations

Information security

New ways of collaborating

We believe that efficiency and safety at industrial sites are driven by improved communication among all stakeholders – both internal and external. By integrating technologies like reality capture and VR, we deliver efficient training and collaboration solutions that enhance learning, reduce costs, and increase productivity.

Effective communication

Real-time collaboration

Increased productivity and cost efficiency

Trusted across different industrial fieldsBe part of the trusted brands that choose us

How it workseSite makes it easy for you

Site Scan

Our experienced surveyors arrive on‑site equipped with advanced 3D laser scanning technology. The process is fast, non‑intrusive, and usually completed within a single working day, allowing your team to keep operations running normally while we digitize your facility.

By the end of the visit, we’ll have captured a complete, high‑accuracy dataset forming the foundation of your site’s digital replica.

.jpg)

Data processing

Once scanning is complete, our team will start the processing of the data. Sit back and relax as our team will get your virtual site ready for you.

We handle everything—from point cloud alignment to panoramic image stitching—ensuring your digital replica is accurate and ready for use.

Delivery & Access

We create your customized eSiteview environment based on the processed data. This includes quality assurance, user account setup and credential delivery.

Your input is minimal—just define the users or provide SSO integration details if needed. Once credentials are delivered, your team can start using the service immediately.

Continuous Support

We support our clients from start to finish—and beyond. Every project includes onboarding training to ensure your designated users adopt the service effectively, maximizing value and cost-efficiency.

We also help you evolve your use of the platform through brainstorming, feature optimization, and collaborative workshops.

Whatever the situation, we’re here to help.

How customers have utilised eSite services

Scan-to-CAD

We performed laser scanning of the loading cell and used it to build an accurate 3D model. The finished 3D model enabled us to test the robot programs in advance in a virtual environment. The customer can now speed up commissioning, reduce production downtime, and develop new solutions safely and cost-effectively.

”We received a highly accurate 3D model of our load cells. This significantly speeds up the design and testing of new programs.”

Sami Tuominen

Technical Manager, Orion

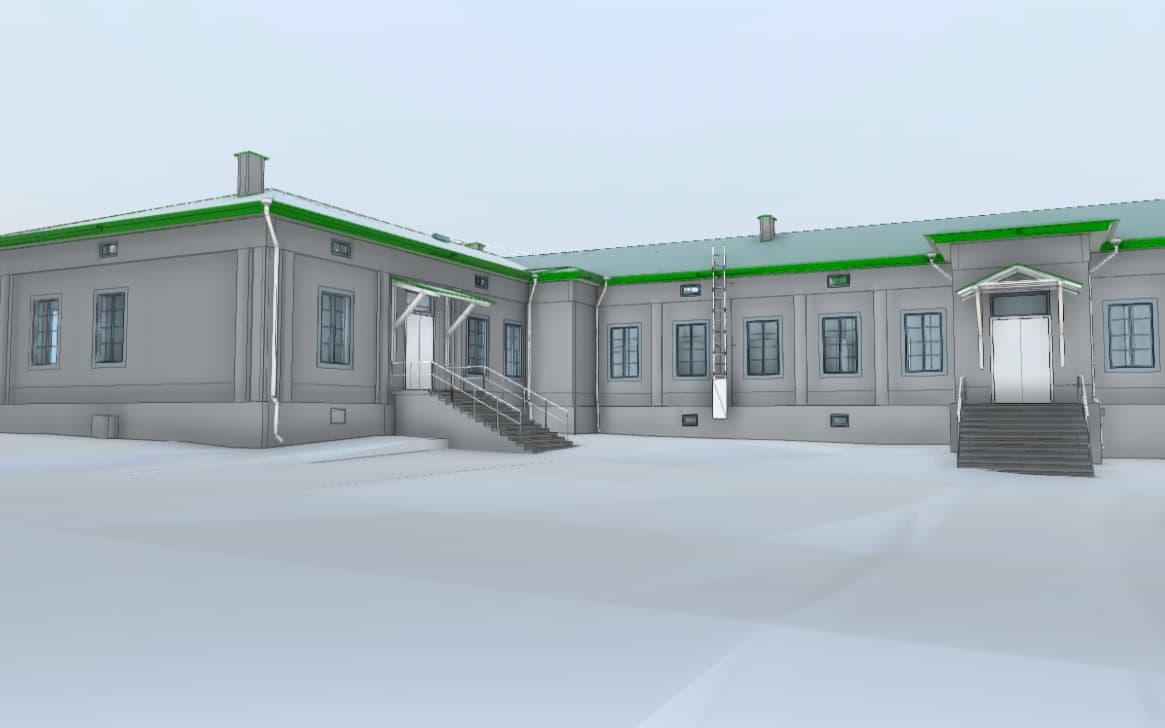

Up-to-date design using laser scanning – Vaasa Kasarmi Area

Vaasan Talotoimi utilized the digital BIM model produced by eSite in the Kasarmi Area daycare center project, which modeled the historic buildings Kasarmi 13 and 14.

Laser scanning, 3D scanning, and aerial photography provided accurate data on the structures and spaces of the barracks without damaging the sites.

The result was a comprehensive digital model that supports the renovation of the Kasarmi area and demonstrates how modern technology can help preserve and develop historic buildings.

Read full story

Added value servicesMake the most of your site data

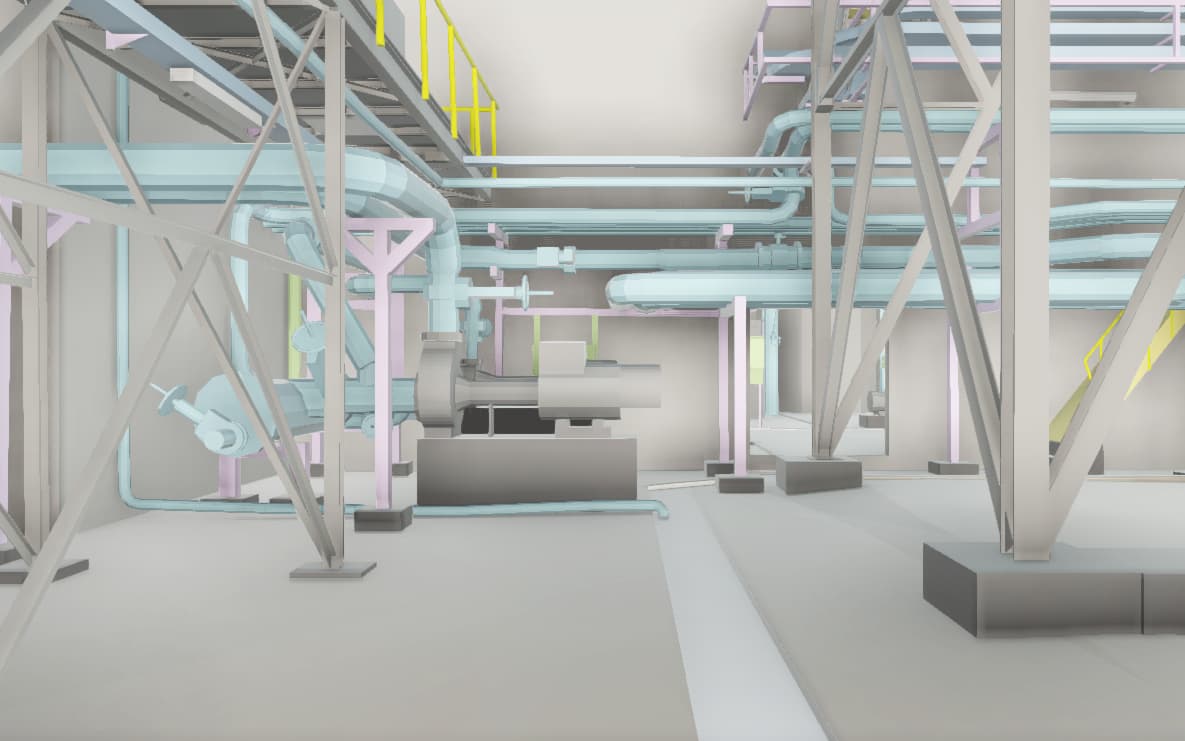

Scan-to-CAD

Streamline your design process with precision. Our Scan-to-CAD service transforms 3D laser scans into ready-to-use CAD models that support efficient planning, documentation, and modification work.

Save time, reduce errors, and take your project to the next level.

Scan-to-BIM

Create a smart digital twin that evolves with your building. Our Scan-to-BIM service delivers accurate and information-rich BIM models directly from 3D scans—an ideal solution for lifecycle management, maintenance planning, and safety design.

Safety training

Virtual safety training that truly prepares your team for the field. Delivered through the eSiteview platform, our training immerses users in a realistic virtual environment where safety protocols and procedures become familiar before arriving on-site.

Alternatively, users can be trained virtually while simultaneously navigating the physical space. A safer start means a more productive workday.

Standalone solutions – eSitetour

Present, onboard, and impress—anytime, anywhere. eSitetour works as a local 3D solution or browser-based experience, bringing your site to life without the need for additional software.

Perfect for customer presentations, training sessions, and stakeholder communication. Easy to use, highly impactful.

Up-to-date design using laser scanning – Vaasa Kasarmi Area information modeling project

Vaasan Talotoimi carried out an information modeling project as part of the Kasarmialue daycare center project. The project focused on the historic buildings Kasarmi 13 and 14, which required accurate documentation to support the design process. eSite was responsible for the digital BIM modeling of the buildings.

The project utilized a variety of measurement and imaging methods, such as precision measurements, room-specific scanning, photography, and aerial photography. These were used to create comprehensive documentation of the buildings' structures and spaces.

The modeling documented all visible structures, including old handmade wooden structures that deviate from current standards. Special attention was paid to ensuring that the structures could be verified without damaging them.

The end result was a comprehensive set of data that included building drawings, room lists, and a segmented model of the different building blocks. This digital model was used to support the planning of the renovation of the Kasarmi area.

The Vaasa Kasarmi Area project demonstrates how modern technology can support the preservation and development of traditional buildings.